Carbon dioxide fixation method

Contributing to carbon neutrality through CO2 fixation technology using Ca/Mg-containing wastes as raw materials! Related patents (1/2)

Overview

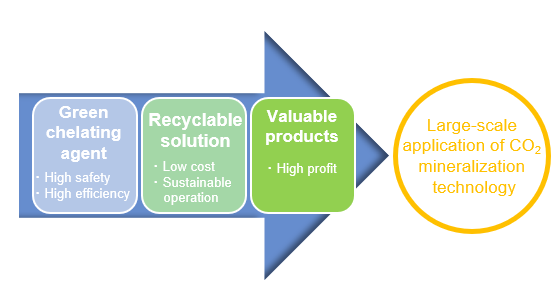

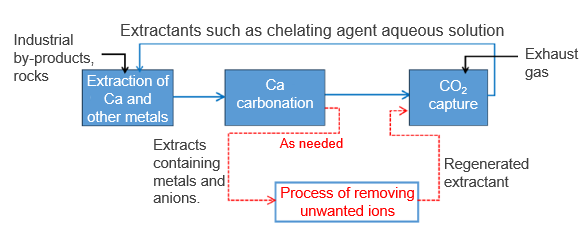

The CO2 fixation technologies so far typically employ alkaline earth metals to fix CO2 by converting it into chemically stable carbonate minerals. However, the conventional technologies are difficult to apply on a large scale because of its slow reaction rate, high cost and potential environmental concerns due to the use of a large amount of pH adjusters.

This invention discloses a novel CO2 fixation process that enables to run under 100°C and ambient pressure without using large amounts of pH adjusters. It can run continuously at low cost by regenerating and recycling of the chelating agent (e.g., GLDA) solution within the process. This invention also enables the production of high-purity carbonates, such as CaCO3, and oxides, such as silica, by using Ca/Mg-containing wastes, including combustion ash, waste concrete, and slag, as Ca/Mg sources. The chemicals obtained in this sustainable CO2 fixation technology, such as CaCO3, are expected to be used in industries such as pigments, rubber, and desiccants.

CO2 fixation under low temperature and pressure conditionss

Product Application

・Carbon Dioxide Fixation Equipment

・Reuse of Ca/Mg-containing wastes

・Commercial use of reaction products in fillers, pigments, fertilizers, and cosmetics productions, etc.

Related Works

[1] Jiajie Wang. et al. Journal of Environmental Chemical Engineering,10 (2022) 107055

[2] Jiajie Wang. et al. Scientific Reports, 11 (2021) 13956

IP Data

IP No. : JP7345791、 US20240042374、CN116635131

Inventor : Noriaki Watanabe、Jiajie Wang、Noriyoshi Tsuchiya

keyword : carbonneutral, carbondioxide, CO2, mineralization, CCU, environment, carbonate, calcium, Ca, industrialwaste

Carbon dioxide fixing method

Efficient CO2 fixation process that allows sustainable reuse of the extraction solution Related patents (2/2)

Overview

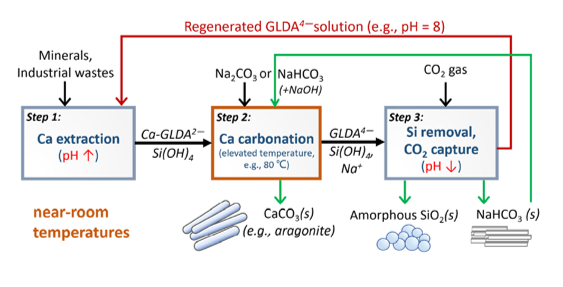

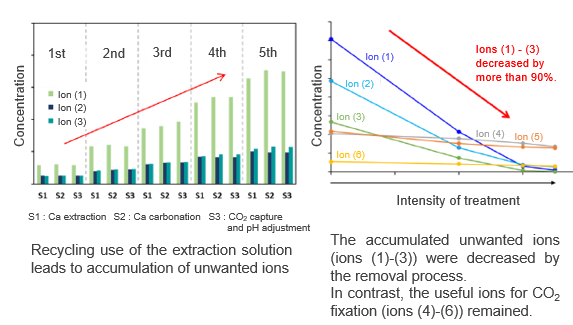

In recent years, significant efforts have been devoted globally to the reduction of CO2 reduction, with CO2 fixation as one of the measures is attracting increasing attention. Conventional CO2 fixation methods face economic and environmental challenges such as the large consumption of chemicals and the generation of wastewater. To address these limitations, the inventors developed a CO2 fixation process using industrial by-products and rocks as raw materials, together with a recyclable chelating agent (e.g. GLDA) aqueous solution as the extraction solution (Patent No. 7345791). However, with repeated use of the extraction solution, unwanted ions from the raw materials accumulated in the solution, leading to a decreased CO2 fixation efficiency. To mitigate this issue, an enhanced, efficient, and sustainable CO2 fixation method was developed by incorporating an additional step for the removal of undesired ions from the extractant.

The present invention is characterized by its effective utilization of underexploited Ca/Mg-containing wastes (combustion ash, waste concrete, slag, etc.) as raw materials for CO2 fixation. Furthermore, it is expected to address the problem that unwanted ions accumulation in the extraction solution during the recycling use of the solution, a challenge that can occur in other CO2 fixation methods.

Various unwanted ions effectively removed from the extraction solution

Product Application

・CO2 fixation

・Reuse of waste containing Ca/Mg

・Removal of harmful ions from waste

IP Data

IP No. : JP2024-088814

Inventor : Noriaki Watanabe、Jiajie Wang

keyword : carbonneutral, carbondioxide, CO2, mineralization, CCU, environment, carbonate, calcium, Ca, industrialwaste