Metal additive manufacturing equipment

To enable more effective regeneration and reuse of metal powder for additive manufacturing.

Overview

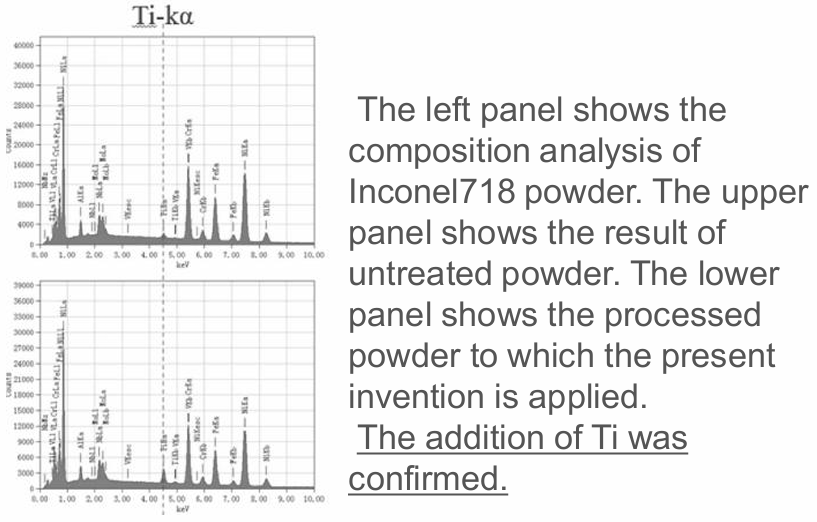

Technology for reusing metal powder used in metal lamination process is attracting attention. One of the conventionally known methods is to mix unused metal powder with recovered metal powder, which is called powder refresh. However, although it is unmelted, some of the recovered metal powder has lost its original composition due to evaporation of highly volatile elements by repeated lamination process. Since powder refresh is not a process to recover the composition of individual particles, further improvement of the reuse method has been required.

The present invention devises an apparatus which enables the supply of a specific element more effectively than ever before, as a result of repeated research focusing on the motion of individual particles of metal powder. As a result of detailed observation and examination of the process of friction and collision, a means for supplying a specific element to the surface of individual particles was clarified, and the problem was solved. This enables the construction of a more effective powder regeneration process in laminated molding, and is expected to lead to cost reduction of molded products.

Effect of Regeneration of Powder - Ti -

Product Application

・Metal additive manufacturing equipment

IP Data

IP No. : JP2025-106095

Inventor : Akihiko Chiba, Keiji Yanagihara, Takemi Chiba

keyword : MetalAdditiveManufacturing, Metal3DPrinting, Recycling, PowderRefresh