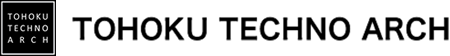

Automatic driving device of screw member

Screw can be driven into hard members from any angle. Continuous automatic driving is also possible with a cartridge.

Overview

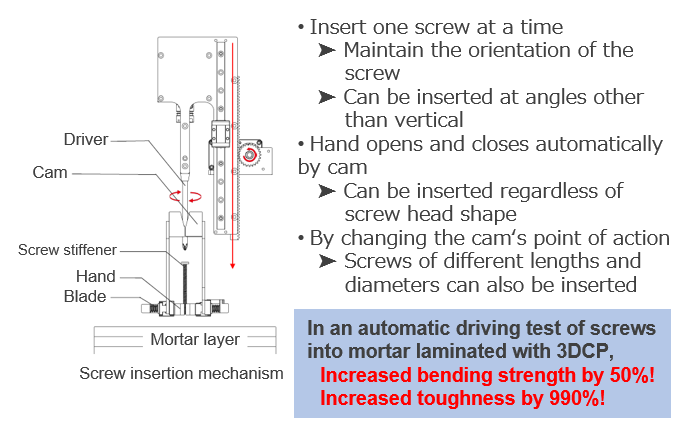

In a 3D concrete printer (3DCP), discontinuous layers are formed between layers of laminated mortar, so it is weak to shear force in the layer direction. Therefore, a measure to increase the strength and toughness has been taken by vertically inserting metal reinforcing materials so as to penetrate the layers. However, the conventional reinforcing method is a method of directly inserting reinforcing materials, and if the cementitious material starts to harden over time, it becomes difficult to insert reinforcing materials as desired. In addition, since conventional reinforcement is carried out only in a specific direction, it is not possible to freely reinforce molding without anisotropy.

The present invention enables reinforcement of molding without anisotropy by a mechanism capable of automatically inserting screws from multiple directions. The screw can be inserted at a desired angle while suppressing displacement by releasing the holding when the screw is driven to a predetermined depth in the object to be driven while maintaining the attitude of the screw. Moreover, the screw can be efficiently driven by providing a cartridge capable of loading the screw.

Features・Outstandings

Product Application

・Reinforcing 3DCP (can be retrofitted to 3DCP)

・Driving screws into wood and building boards

・Other Automatic screw driving robots for furniture and home appliances

Related Works

[1] Concrete Engineering Annual Conference 2024 Proceedings

IP Data

IP No. : JP2024-89372

Inventor : OHNO Kazunori, EGAWA Ryo, NISHIWAKI Tomoya, KOJIMA Shotaro, OKADA Yoshito

keyword : 3DCP, screw, Automatic construction, Stiffener