Supercritical & Subcritical Fluid System

High-Productivity, High-Quality Manufacturing for Pharmaceutical and Food Ingredients

Overview

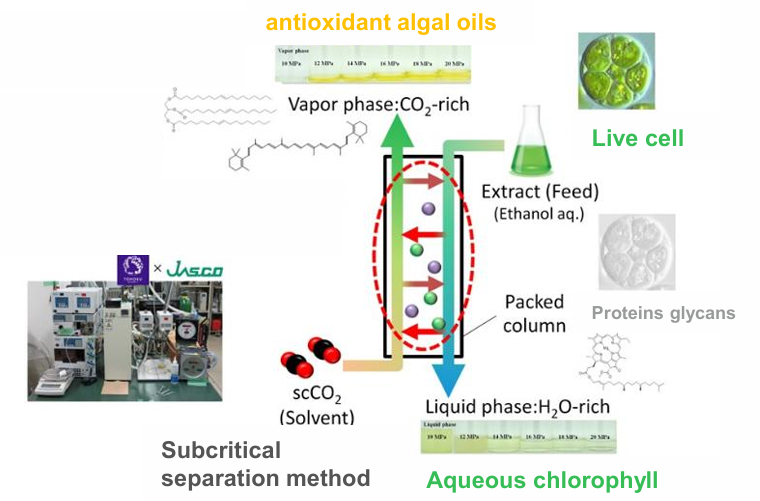

The inventors have developed a unique subcritical solvent separation method using three green solvents—CO₂, ethanol, and water—to enable safe, eco-friendly production of pharmaceutical and food ingredients. Conventional supercritical and subcritical processes often face slurry freezing and clogging due to adiabatic expansion, reducing productivity and increasing maintenance time and cost. The proposed system prevents these issues by creating a controlled pressure difference between gas and liquid phases in the separation column, enabling a safer and more efficient extraction and manufacturing process.

◎High productivity enabled by continuous separation and collection

◎Handles slurry without clogging, reducing pretreatment time and preventing degradation of target compounds

◎No harmful organic solvents, ensuring safer and cleaner operations

Concept of the subcritical separation method

Product Application

・High-productivity, high-quality manufacturing of pharmaceuticals, foods, and supplements

・Separation of colors, flavors, and aromas in food and beverage production

Related Works

IP Data

IP No. : WO2024/128121

Inventor : Masaki Ota, Hiroshi Inomata

keyword : supercritical, subcritical, biomass, microalgae, energy